Here’s how Yamaha's Japan factory approaches sustainability

For the motorcycle brand, sustainability starts here

Recently, we covered several new prototypes from Yamaha Motor Company Limited that make use of new-energy propulsion systems such as the Proto HEV and PHEV, as well as the Proto BEV that debuted at the Japan Mobility Show 2025.

KEY TAKEAWAYS

Where is Yamaha's sustainable paint line located?

The paint-lie is found in its Iwata factory in Japan.How much heat loss does the new installation save?

The new paint line saves up to 60 percent of heat loss. Photo by Juan Paulo Papa

Photo by Juan Paulo PapaHowever, the company’s strides in sustainability are not only reflected in the products it presents, but also in how it finds ways to cut down unnecessary use of energy in its manufacturing processes.

Not too long ago, Zigwheels Philippines joined select motoring journalists from various countries to visit Yamaha Motor Company Limited’s newly established CN1 carbon-neutral mass-production painting line in Iwata, Japan.

Here’s what we discovered.

Electricity replacing fossil fuels

One of the key transitions undertaken by the company’s painting line is the use of electricity in lieu of fossil fuels.

Electric power is now what propels movement in the factory’s pre-treatment, painting, baking, and drying functions. This move began in February, so the change in power used to run the said lines has now been ongoing for approximately nine months.

Photo from Yamaha Motor Company, Limited

Photo from Yamaha Motor Company, LimitedIt was explained that to achieve an all-electric operation for the new CN1 painting line, Yamaha Motor Company Limited combined — and even cleared — a variety of technical requirements, such as:

- Paint that can be used at lower temperatures

- A more compact facility design

- Insulation and air supply recycling technologies

Photo from Yamaha Motor Company, Limited

Photo from Yamaha Motor Company, LimitedIn doing so, the manufacturer has reduced wasted heat by approximately 60 percent.

Other stories: |

Man, machine

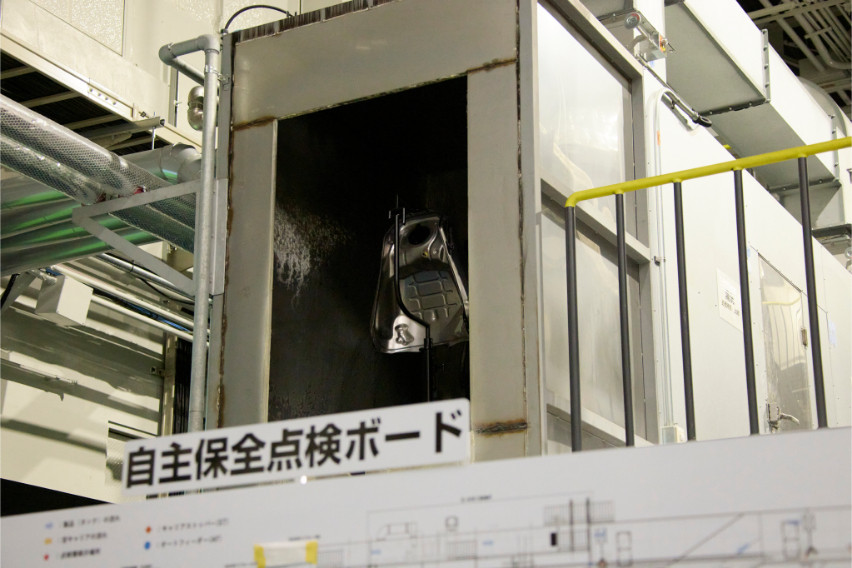

Many of the procedures in the painting line are done by robots. These ensure precision in things like how paint is applied to the tank covers.

Photo from Yamaha Motor Company, Limited

Photo from Yamaha Motor Company, LimitedDuring the factory tour, participants witnessed automated arms move and paint the said components with accuracy. And while some jobs are done by robots, it was good to see that these motorcycle parts still get some human touch.

Photo from Yamaha Motor Company, Limited

Photo from Yamaha Motor Company, LimitedFinal touches to these covers are applied by hand by skilled craftsmen.

A Yamaha initiative

After the tour, Yamaha Motor Company Limited confirmed that the move to make its paint line in Iwata more sustainable was made by the company itself.

Many of us know that some brands follow government mandates that have policies enforcing carbon neutrality. But the Japanese motorcycle manufacturer took it upon itself to reduce its carbon footprint, reinforcing its position as a brand that sets “industry first” initiatives.

Photo from Yamaha Motor Company, Limited

Photo from Yamaha Motor Company, LimitedFor those wondering, some hundreds of motorcycle fuel tank covers are produced in the said Iwata factory on a daily basis.

Also read:

Here's why Yamaha Aerox no longer carries the Mio badging

Yamaha Motor PH produces OST with Nik Makino

WATCH: Yamaha Motor PH showcase Sniper 155, Mio Aerox in short film

Connect with us through our various social media pages:

Facebook: https://www.facebook.com/ZigWheelsPhilippines

Instagram: https://www.instagram.com/zigwheelsph/

Yamaha Motorcycle Models

Trending & Fresh Updates

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

Yamaha Featured Motorcycles

- Latest

- Popular

Latest Yamaha Motorcycle Videos on Zigwheels

Yamaha Motorcycle Articles From Carmudi

- journal