Nissan plans to put more carbon fiber in your car

MANILA: Expect more carbon fiber parts in future Nissan vehicles as the Japanese automaker discovers a new process that speeds up its development for use as auto parts.

Carbon fiber reinforced plastics, or CFRP, is lightweight yet extremely strong and can be used to make cars that are safer and more fuel efficient. It can also lower a car’s center of gravity when used on upper body parts, making it more agile and exciting to drive.

Nissan’s new process in mass-producing CFRP parts has cut the lead time to develop such components by as much as half, and cycle time for molding by about 80%, compared with conventional methods.

Carbon fiber is more expensive compared to other materials like steel and is difficult to shape but Nissan found a new approach to the existing production method known as compression resin transfer molding.

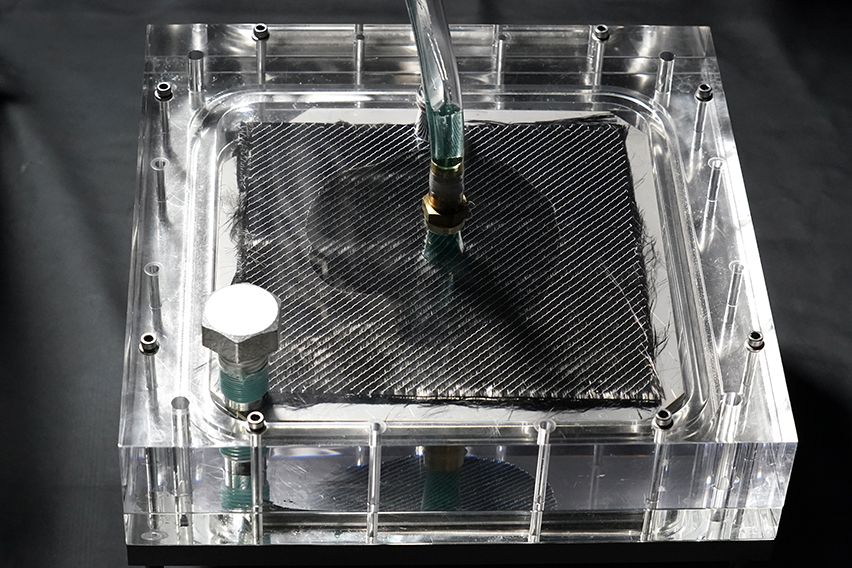

The existing method involves forming carbon fiber into the right shape and setting it in a die with a slight gap between the upper die and the carbon fibers. Resin is then injected into the fiber and left to harden.

Nissan’s engineers came up with a technique that accurately simulates the permeability of the resin in carbon fiber while also visualizing resin flow behavior in a die using an in-die temperature sensor and a transparent die. The result of the successful simulation was a high-quality component with shorter development time.

Photos from Nissan

Also read: WATCH: Musicians rework hit song using Nissan X-Trail sounds

Sell your car at the best price

Verified and genuine buyers

Verified and genuine buyers

Nissan Car Models

Trending & Fresh Updates

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

Nissan Featured Cars

- Latest

- Upcoming

- Popular

Latest Nissan Car Videos on Zigwheels

Nissan Car Articles From Carmudi

- journal

- insurance