Porsche 3D-prints pistons for the 911 GT2 RS

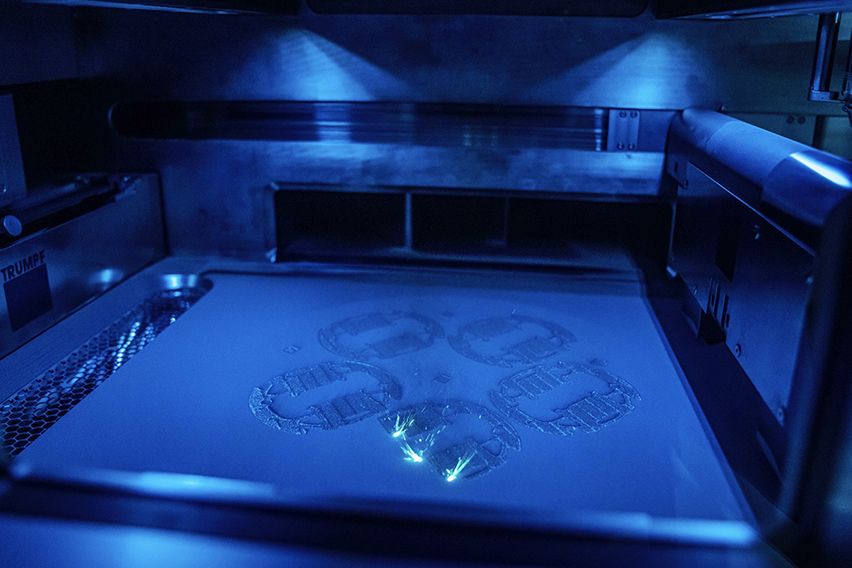

MANILA: For the first time, Porsche is now 3D printing pistons for the high performance engine of the 911 flagship model, GT2 RS.

This process allows the pistons to be 10% lighter and made with a structure optimized for the loads acting on the pistons. It will also come with an integrated and closed cooling duct in the piston crown, which wouldn’t have been possible under conventional construction.

“Thanks to the new, lighter pistons, we can increase the engine speed, lower the temperature load on the pistons and optimize combustion. This makes it possible to get up to 30 PS more power from the 700 PS biturbo engine, while at the same time improving efficiency,” said Frank Ickinger from the advance drive development department at Porsche.

The principle behind 3D printing is building a component layer by layer without using a special tool or mold. This makes it possible to construct any geometric shape.

High-purity metal powder under a laser metal fusion process was used to make the pistons of the 911 GT2 RS. The laser beam heats and melts the powder surface based on the contour part.

The quality and performance capability of each component were validated using measurement technology from Zeiss.

Aside from these performance parts, Porsche has been manufacturing 3D-printed bodyform full bucket seats for the 911 and 718 since May 2020. Customers can even choose between three firmness levels – hard, medium, or soft.

The release level for the clutch of the 959 is now being 3D-printed along with 20 reproduced parts for Porsche classic models.

Photos from Porsche

Also read: Porsche's first fully electric sports car is now here

Sell your car at the best price

Verified and genuine buyers

Verified and genuine buyers

Porsche Car Models

Trending & Fresh Updates

- Latest

- Popular

You might also be interested in

- News

- Featured Stories

Porsche Featured Cars

- Latest

- Popular

Latest Porsche Car Videos on Zigwheels

Porsche Car Articles From Carmudi

- journal